Elevator Hazard Monitoring and Mitigation

Grain Elevator Monitoring, and Fire and Explosion Mitigation

Discover a complete modern system dedicated to protecting your bulk handling machinery at all times. The M-Jet System can be accurately set to monitor, manage, and analyze all defects, and report on productivity of your machines in real time. Information can be accessed day or night across the globe directly to your laptop, tablet, or mobile phone. Offering a complete range of hazard monitoring and safety equipment to handle a plant of up to 120 conveyors gives our customers the most economical of solutions available on the market.

Boss Products offers a complete range of engineered industrial safety solutions to mitigate the hazards of dust explosions. Environmental Solutions offers expert installation of all Boss Products grain elevator hazard safety equipment.

CALL TOLL FREE 1-866-438-7891

Grain Elevator Hazard Monitoring, and Fire and Dust Explosion Mitigation

VIGILEX® Flat Explosion Vent Panel VL

The VIGILEX Flat Explosion Vent Panel VL is suitable for all applications with low vacuum operating pressures. Typical applications include dust collectors, conveyors, cyclones, elevators, and silos.

The VIGILEX Flat Explosion Vent Panel VL is specifically designed to satisfy low pressure explosion venting requirements. They are designed with an integral gasketed flange that covers the breaking points, ensuring strong mechanical durability. A wide variety of standard and custom sizes and bolt patterns are available.

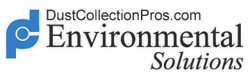

M-Jet Hazard Monitoring Devices

M-JET SYSTEMS are specifically designed as an early warning system to alert facilities to potential sources of explosion ignition. The hazard monitoring devices are able to accurately monitor, manage and analyze productivity, operating conditions and hot-spots that could lead to additional equipment damage, costly repairs and explosion hazard. Data Reports include dangers associated with speed control, misalignment, level & choke control, bearing and motor temperatures.

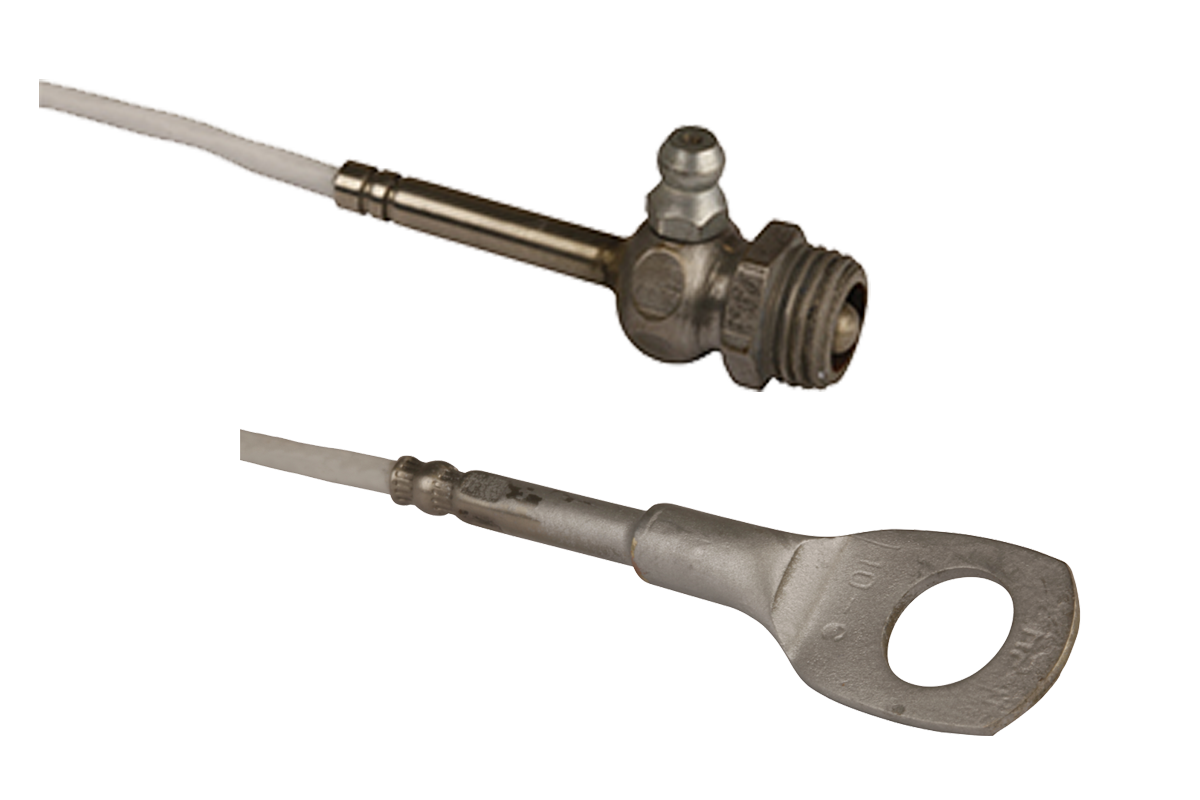

Bearing Temperature Sensors

Two options are available for the VIGITHERM Bearing Temperature Sensors. Both are PT 100 Class B ATEX Certified sensors that can be connected directly to a central control area or to the hazard monitor M-JET+.

The VIGITHERM GST 100 LG is rated for ATEX Zone 21, Dust.

The VIGITHERM GST 100 HX is rated for ATEX Zone 20, Continuous Dust.

Motion Controller Options

Motion controllers are specially engineered to control the constant speed of a rotative shaft. It is frequently installed on buckets’ elevators, chain conveyors, mixers, locks, etc.

The VIGIRO® IP26 includes a pulses ometer which is either connected on a preset machine or on an independent security module to ident the nominal pulses’ frequency at the outlet.

The VIGIRO® SV26 was engineered to control the constant speed of a rotative shaft to detect any fault in the case of a dangerous under speed.

Belt Alignment Systems

The VIGIBELT® TOUCH is a lateral movement sensor that detects run-out of elevator belts or conveyor belts, and at the same time the run-out of the lift pulley. It reacts to the pressure of the belt coming into contact with the front face of the sensor.

The VIGIBELT CDM80C® is an elevator belt alignment system which has to be placed on an elevator in order to avoid any friction between the belt and the inner sides of the elevator’s leg.

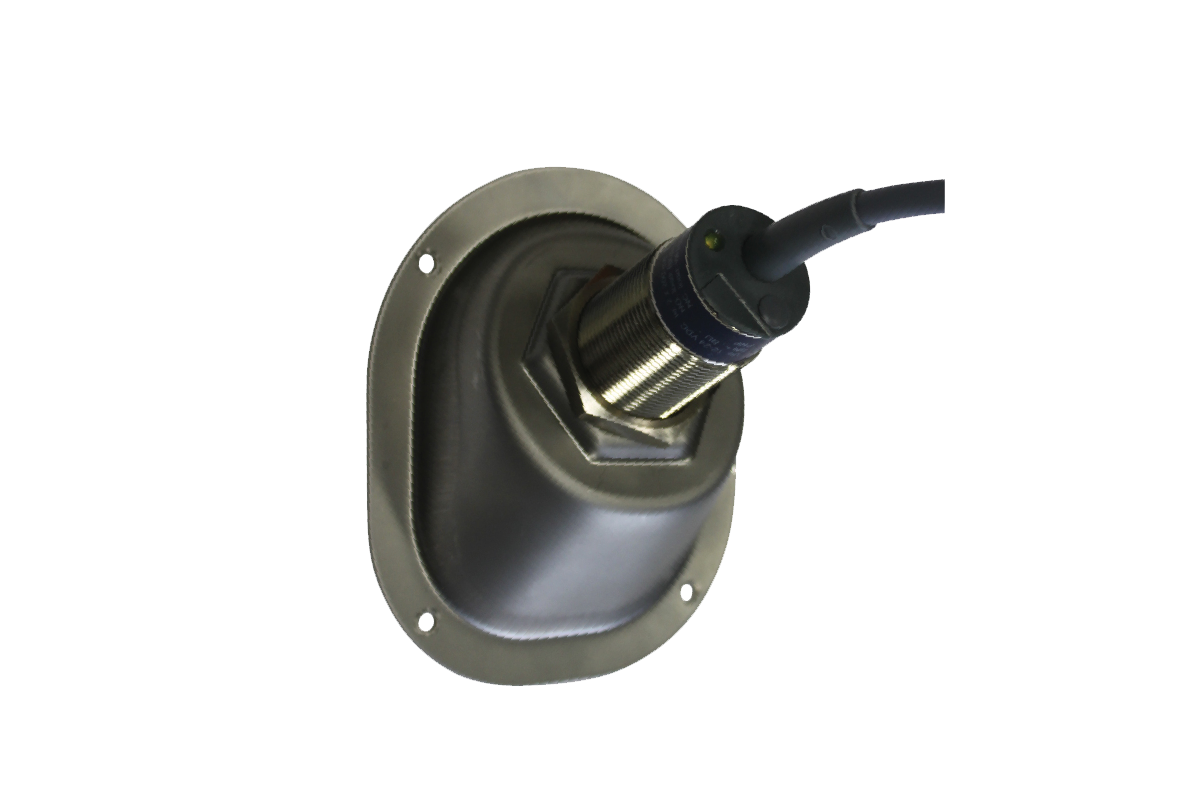

Level and Choke Sensors

The VIGIMAT DNC 30 is a level indicator and jam capacitive detector. The VIGIMAT DNC 30 devices can be connected directly to a central control area or to the hazard monitor M-JET+.

Customers also viewed: Dust Collector Spark Trap, Raptor® Fire and Explosion Prevention, Fire Isolation & Diversion, Dust Collector Explosion Vent Panels, and Dust Collector Explosion Isolation and Diversion Valves.